CHAPTER 3

Design, Specifications, and Component Selection

JEFF HOCH, LICENSED ARCHITECT

JORGE IBACACHE, SI, CGC, CODE COMPLIANCE

CONSULTANT

QUALITY BUILT®

Construction is experiencing a design renaissance. The integration of digital models into the construction processes is growing at an amazing rate. Drawings are rarely copied and distributed for takeoffs but, rather, shared through Web portals. In the not-so-distant future, builders will share 3D digital data models rather than drawings.

The application of digital drawings will improve the quality of construction and help promote continual process improvement. Digital models allow for manufacturers to encode product and manufacturing information (PMI)

standards, which can be used to predict performance under occupational load, eliminate wasted materials, ensure compatibility between products and systems, and define maintenance protocols.

With the recent but limited advantage of computer aid and modeling software, designers are able to reduce the risk of failing systems by properly planning the integration and design of the components. Structural engineers can model entire buildings, from the foundation to the roof, on computer simulators and determine how the entire structure will behave and perform during construction, during its typical intended use, and in the event of a disaster. This greatly aids engineers in the selection of the best products. Electrical and mechanical systems are also benefiting from the use of computers. Designers can use the computer models to calculate the energy efficiency of buildings to determine the best combinations of insulation, building components, and mechanical systems.

These innovations do, however, have side effects. Systems are no longer designed for service load; instead, they are designed for reducing factor loads. In other words, to minimize installation cost, systems are now designed to operate almost to the failing point with very little room for error. If by any chance the trade contractors use incompatible or nonapproved products, the entire system will fail. If the wrong type of weld is used on the steel connection of a concrete beam of a precast parking structure, then the entire building would collapse if it is subject to loads that exceed the designed capacity.

There are other barriers that are preventing the immediate widespread adaptation to digital data models, including a lack of personnel who are properly trained to use the software efficiently and effectively, an inability to integrate with other systems, and an obvious lack of testing standards and protocols to stress-test the digital data designs to ensure performance and prove correctness. The test software that does exist today is too expensive to utilize in most residential construction processes.

So if digital models are not widely available today, why bring them up? Because construction is more complex than ever, and the technology platforms to review the integration of systems and components are not in general use yet. Until systems can verify engineering calculations, work out sequencing (particularly in complex intersections of buildings), and verify that all of the selected products and materials can perform in harmony with one another, all while being environmentally sound, builders and design professionals need to utilize “best practices.” Best practice is defined in Wikipedia® as “a method or technique that has consistently shown results superior to those achieved with other means, and that is used as a benchmark. In addition, a ‘best’ practice can evolve to become better as improvements are discovered. Best practices are used to maintain quality as an alternative to mandatory legislated standards and can be based on self-assessment or benchmarking” (Feb. 21,2014).

Best practices for the design of construction projects should include protocols for selecting your design team, capturing and communicating design attributes, and reviewing requirements. Properly designed and reviewed projects have fewer defects, less wasted materials, fewer change orders, fewer construction delays, less costly rework, and so on. Best practices in creating design drawings and documents, making product and material selections, and communication of specifications will still be required for proper integration even when digital models are available and should be established now.

Structure Your Design Team for Success

The standard procedure for designing a project is to engage an architect to create the design and specifications for the project and then later assemble a team of specialty designers to fill in the blanks. Builders and developers should engage their entire team at the beginning and place one person (or entity) in charge of coordination. Their role and responsibilities should include overall supervision of the design process, coordination of communication to avoid incorrect assumptions or miscommunications, prevention of delays in responses or incomplete responses, prioritizing tasks and assigning deadlines, and facilitating design compatibilities. Whoever you plan on utilizing in this capacity should be responsible for creating and communicating the standards for design information and format, and must also control the flow of information. Each piece of information must be submitted in a logical, progressive manner to organize the flow of data input, which must continue to flow through design completion.

Integrate Your Design Team with the Construction Team

It is amazing how little interaction there is between the design team and the construction team prior to site preparation on a new project. At Quality Built™, we recommend that builders and developers integrate the two departments and incorporate a knowledge base review prior to beginning any design work. It is important that someone with extensive construction knowledge be included on the design team and placed in the information flow to create a comprehensive knowledge base on the project.

Creating a knowledge base involves identifying the individual responsible for managing the knowledge base, gathering documentation of analysis of past and present projects, and correlating this to new action items based on lessons learned. The knowledge base owner is responsible for making assignments to internal experts to properly and consistently produce meaningful content. If no one is assigned and monitored, then meaningful content will never be created.

Knowledge base owners must continually monitor issues that should be documented, such as internal customer service records, change orders and request for information (RFI) frequency, and content from past projects. They also must search the Internet for product recalls or construction defect litigation in their area. Content must then be stored where it can be reviewed by individuals or teams to identify opportunities for improvement. Improvements are typically communicated through changes in processes, the level of detail in construction documents, product and material specifications, installation standards, or quality manuals. Technical content should be reviewed prior to publication. All content should identify the creation date and all subsequent updates. A truly valuable knowledge base does not let any content become stagnant, and does not duplicate information by producing similar documents.

The main objective is to create a set of design documents that captures the project requirements and details them out to eliminate incomplete details, missing details, ambiguous details, and details that have historically failed. It is important that each project begin with rigorous analysis of the design criteria along with complete cooperation from the owner. Many projects fail or experience significant increases in costs due to oscillating owners. When selecting your design team, ask what system they have to capture and administer design changes. Look for a design team that utilizes rapid iteration production (commonly used in software development). Rapid iteration production of design documents will immediately alert other specialty designers and the contractors of any changes that may impact the project or value chains. Projects that integrate construction personnel in the design process have faster, smoother starts since the team is already familiar with the drawings, resulting in fewer RFIs throughout the project.

Have Your Drawings Reviewed by Professionals

In the absence of an internal knowledge base system and technical staff, many builders and developers will utilize third-party quality assurance firms to perform a comprehensive technical peer plan review to help identify constructability issues and eliminate some of the most common defects. If you do utilize a third party, you should get them involved in the project as early in the design stage as possible to help evaluate products and materials, define document expectations, and eliminate design defects by bridging communication gaps between the various design professionals. Firms with experience in evaluating failed buildings, preparing cost-effective repair recommendations, and/or performing quality assurance/quality control during the course of construction are preferred over other architectural firms. At Quality Built™, we also use design reviews as an opportunity to clearly define the quality assurance standards for each project by incorporating information from the specific products and materials to be used and the recommended sequencing of materials during the installation process. A comprehensive evaluation of drawings can cost several thousand dollars, but the payoffs can be immense.

Even if the designer is referencing manufacturer’s recommendations, it is advisable to incorporate those instructions into the details. Manufacturers typically service multiple regions and may have only one installation guide for the multiple uses of the component to be installed. For example, window installers are no longer installing windows simply to provide light and ventilation into a room; they are also providing a weather barrier and, in some areas, wind and impact protection. Installers now must be aware of the climate and site requirements of each window, which may differ from those in other rooms and buildings.

One of the aspects evaluated during a technical peer plan review is the completeness of details. What constitutes a complete detail?

A complete detail in the simplest terms includes the following:

• Leader lines pointing to all relevant items in the detail

• Notes indicating the type of product(s), name of product, what it needs to be compatible with, installation sequence, tolerances, and procedures

• Clear lines so that you can differentiate between the items in the detail (for example, you can tell the flashing from the building paper because they do not merge into one line)

• Clear indications for the proper integration of the different items

• Critical dimensions

Complex assemblies often require one reference detail with several enlarged details from that reference in order to be considered complete and clearly indicate how the various layers/products are to be integrated.

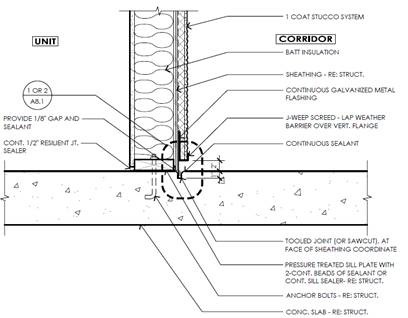

See the following for an example of incomplete or incorrect details:

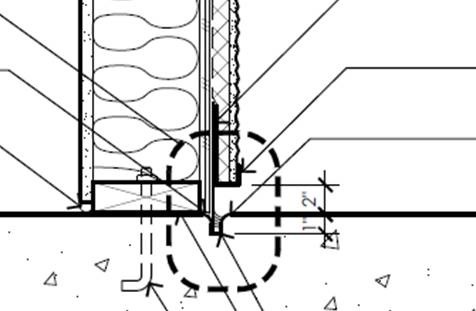

In its entirety, the previous detail appears to be complete. However, an enlarged view of the detail will reveal that it is confusing and incorrect.

In this close-up example, the integration of the components shown becomes confusing as graphically the weather-resistive barrier, indicated with dashed lines, and the continuous galvanized metal flashing, a thin vertical line, merge with the thick black line of the J weep screed. In addition, the arrows get lost.

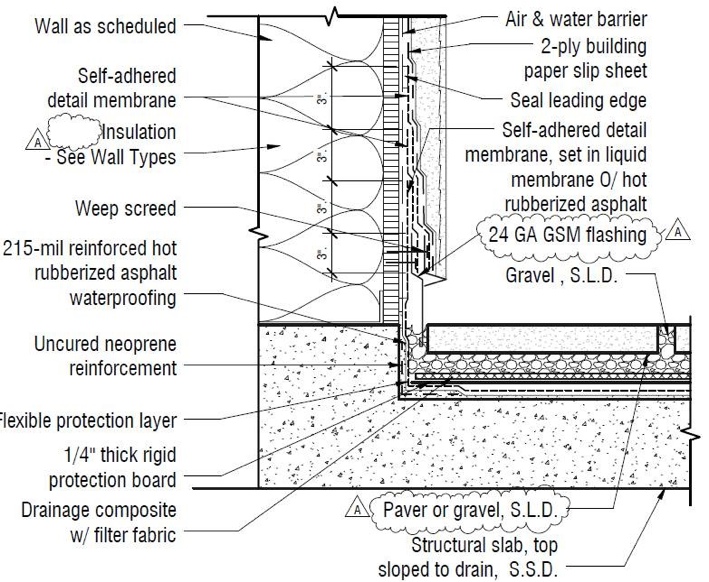

Now see the difference in the next example of complete details:

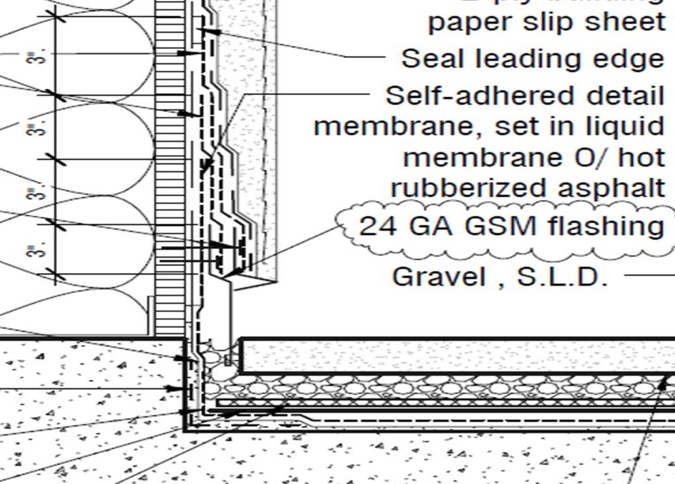

While the overview of this detail may appear more confusing than that of the incomplete detail above, the enlarged detail will show that this detail is complete and accurate.

Notice how this detail shows clearly the various layers of flashing and how they are integrated (lapped). In addition, all other graphic elements, including arrows, are clearly visible.

Specifications

The construction industry uses three common methods to specify construction materials: descriptive, reference standards, and performance. All of these methods are typically utilized within the specifications of a single project. Requirements are expressed in an “open specification” format, which allows for the selection of products from any manufacturer as long as the product meets all of the requirements. A “closed specification” identifies a product by make and model and is generally not allowed by code; as such, it is usually avoided by design professionals in order to limit their liability. Descriptive specifications provide a narrative of a process that must be completed at a particular stage of construction or as part of an installation process. Some examples are the method required to prepare a surface for an adhesive, communicating a standard for prepping materials such as plaster sand, and defining curing periods for specific components.

Reference standards include the industry standard or testing standard that the product or material must meet or exceed, such as ANSI, ASTM, or UL. Sometimes, reference standards may name a government entity that must recognize and approve of the product, such as the “State of California” or “Miami-Dade Approved” in Florida. These standards are usually easy to identify as the approved products typically list the approval on their specification sheets and product labels. Performance specifications identify the standards that a product or material must perform to post-installation and the conditions in which it must perform. These specifications do not give any reference as to how they may be achieved, making performance specifications a purchasing department’s nightmare. In fact, many design professionals do not always understand the impact of one material or system’s operational influence upon the performance of another system or component. Additional complexity is added when a home is designed as an energy-efficient or sustainable environment.

It is crucial that a technical person review any and all products selected by the purchasing department to validate that the product meets all specifications. This validation should also be a part of the change order process.

Performing Comprehensive Research Prior to Making a

Material Selection

Purchasing agents and/or project managers can be pressed for time and may want to select the first product that meets the performance specifications. As stressed above, the selection of specific materials and components may be more complex than others, and material selections need to be made in a logical order to ensure integration compatibility. For example, if you know that your windows have a complex performance specification, then you should select the windows prior to selecting the systems and components that will integrate with that window, including sealants, weatherization barriers, and exterior cladding systems.

Product incompatibility can cause deterioration of materials, which often results in significant construction defects. The most common occurrences involve contact between dissimilar metals causing corrosion and eventual failure, metals and aggressive soils, and chemical incompatibilities involving sealants, adhesives, or caulking. However, all materials are subject to incompatibility failures. Materials may even have environmental incompatibilities such as acceptable temperature ranges for application or the ability to sustain only limited exposure to sunlight. All of these factors must be taken into consideration prior to making your final material selection. There are a number of reference guides specifying what products and materials are incompatible with one another. There are also several websites that can be consulted for product approvals, such as Engineering Express.

Green products may have additional complexities. For example, when searching for a sustainable wood floor product, the builder or purchasing agent must also research the origin of the wood and the supply-chain reporting provisions in order to comply with the Lacey Act. There are many lessons to be learned from the government raids on Lumber Liquidators in late 2013. Builders do not want to destroy their reputation as a green builder because of one ignorant material selection.

Verification in the Field

The process of inspecting for proper material installation and ensuring potential incompatibilities in the field are addressed in a separate chapter of this book, along with how to detect counterfeit building materials. However, it should be noted that verifying that trade contractors or others never make product substitutions and documenting the installation of specified products are vital parts of risk management.