Quality Built® Tech Alert

December 10th, 2015

Volume 2, Issue 14

By: Jeff Hoch

Quality Built Forensic Architect

Field Consultant and Technical Services Technician

Dryer Duct Length Best Practices

Reducing The Risk of Dryer Fire

The maximum length for dryer exhaust ducting is defined in the International Fuel Gas Code (IFGC) Section 614.6.5. Over the years, these Code requirements have changed. To further complicate matters, so have the dryer manufacturers’ claims of the length of exhaust duct that their dryers will utilize properly. This Tech Alert will explain why the length of the dryer exhaust is important, the potential risks posed to a builder if exceeding maximum length, and provide guidance on how to address common problems associated with dryer exhaust.

Life Safety/Fire Issue

The length of the exhaust plays a large part in the ability of the dryer to expel lint all of the way out of the duct. While the dryer lint screen should trap the majority of the lint, a surprising amount still gets into the duct. Both experience and physics tell us that the longer the duct length, the risk of lint accumulation and causing a fire is increased. If this lint is not expelled all the way out of the duct it can create a blockage.

The length of the exhaust plays a large part in the ability of the dryer to expel lint all of the way out of the duct. While the dryer lint screen should trap the majority of the lint, a surprising amount still gets into the duct. Both experience and physics tell us that the longer the duct length, the risk of lint accumulation and causing a fire is increased. If this lint is not expelled all the way out of the duct it can create a blockage.

The photo above is reflective of this lint buildup in the dryer duct and is not uncommon to see after years of use. This blockage can result in a fire in the dryer or the dryer duct.

The National Fire Protection Association (NFPA) prepared a report that included statistics for fires based on the cause of the fire for the years 2006 through 2010. The below is a table we prepared based on the data in that report:

Fires Related to Clothes Dryers2006 - 2010 |

||

Average # of |

||

|

Fatalities |

Injuries |

Dollars in damage |

|

29 |

402 |

$192,000,000.00 |

Cumulative Totals |

||

|

Fatalities |

Injuries |

Dollars in damage |

|

116 |

1,608 |

$768,000,000.00 |

Fire is not the only concern for those with a gas-fired dryer as the duct system is also used to exhaust the products of combustion. A clogged duct can cause a buildup of carbon monoxide in the laundry room which can also be very hazardous.

It is important to remember that construction defects that cause bodily injury are not subject to statutes of limitation and often result in the highest awards.

The photograph on the right, reproduced with permission from the Tualatin Valley Fire and Rescue, shows a dryer that was the cause of a fire.

Code Allowances

While we will reference the 2012 IFGC in this article, the language in these sections is the same in the 2015 Codes.

- Duct length shall be as determined by either IFGC Section 614.6.5.1 Specified Length or IFGC Section 614.6.5.2 Manufacturer’s Instructions.

- 614.6.5.1 Specified Length:

- 35-foot maximum length from the connection of the transition duct (short flexible duct that connects the dryer to the permanent dryer duct) to the external termination.

- Where fittings are utilized, the maximum length of the exhaust duct shall be reduced in accordance with Table 614.6.5.1.

- 614.6.5.2 Manufacturer’s Instructions:

- Length shall be determined per the manufacturer’s installation instructions, a copy of which shall be provided to the Code Official.

- Table 614.6.5.1 shown below includes the reductions based on degree of bend (either 45 or 90) and the diameter of the duct.

TABLE 614.6.5.1*

DRYER EXHAUST DUCT FITTING EQUIVALENT LENGTH

DRYER EXHAUST DUCT FITTING TYPE |

EQUIVALENT LENGTH |

|

4 inch radius mitered 45-degree elbow |

2 feet, 6 inches |

|

4 inch radius mitered 90-degree elbow |

5 feet |

|

6 inch radius smooth 45-degree elbow |

1 foot |

|

6 inch radius smooth 90-degree elbow |

1 foot, 9 inches |

|

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 degree = 0.01745 rad. |

|

* The Table includes 8 inch and 10 inch ducts as well but we limited our inclusions to the 4 inch and 6 inch as these are the most common in residential units.

How to Properly Apply the Code

It is worth noting that the Code ‘establishes the minimum requirements’ and meeting Code does not mean that what you are doing will be effective and safe (2012 IBC Section 101.3).

This is especially true when misunderstandings of how to properly apply the Code are combined with misunderstandings of the manufacturer’s requirements. On top of this, is the fact that many do not understand the risk associated with an improperly designed or installed dryer exhaust system. These misunderstandings can lead to incorrect calculations and incorrect installations which could lead to someone's life being put at risk.

So how do the misunderstandings occur? Let’s look at a hypothetical:

- Let’s take a hypothetical laundry and assume the duct layout runs up in the wall and then through a chase in the ceiling over an adjacent bedroom to the outside. We will assume the following facts with regards to the duct run:

- The vertical length up the wall is 6 feet.

- The duct needs to jog around an HVAC duct along its way to the outside wall so the total horizontal run is 9 feet.

- There are four 90-degree elbows at the following locations:

- One at the transition to the wall.

- One at the transition to horizontal above the ceiling.

- Two more to jog around an HVAC chase.

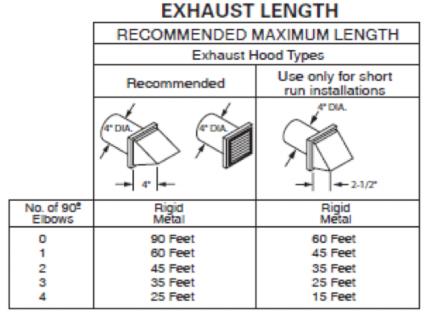

- The dryer manufacturer indicated by the builder has provided the chart in image 1 for their dryer.

- The termination cap will be the 2 1/2-inch opening the manufacturer recommends only for short runs.

Using the two different code options we can calculate the effective length of the duct run:

- Using IFGC Section 614.6.5.1 Specified Length - the effective length would be

calculated as 6 + (4 x 5) + 9 = 35 Feet - Using IFGC Section 614.6.5.2 Manufacturer’s Instructions - Using the table provided in Figure 1 by the hypothetical manufacturer because of the four 90-degree bends the allowable length would be 15 feet.

So the effective length would meet the code allowance but not the manufacturer’s allowable length. This means the dryer may not be able to provide enough force to completely blow the lint all of the way out of the duct. Many people would see the manufacturer’s literature which would promote the dryer as capable of long duct runs and believe that it would at least be capable of the length the code allows. As can be seen the actual length the manufacturer would recommend under these conditions would be less than half the code allowable length.

Now let’s change the hypothetical slightly so we can look at another issue. Let’s assume the following:

- The duct layout runs up in the wall and then through a chase in the ceiling over the adjacent garage to the outside.

- The vertical length up the wall is 6 feet.

- The total horizontal run is 25 feet.

- There are two 90-degree elbows at the following locations:

- One at the transition to the wall.

- One at the transition to horizontal above the ceiling.

- The dryer manufacturer has not been indicated by the builder.

Now let’s use the two different code options to calculate the effective length of the duct run:

- Using IFGC Section 614.6.5.1 Specified Length - The effective length would be

calculated as 6 + (2 x 5) + 25 = 36 Feet. - Using IFGC Section 614.6.5.2 Manufacturer’s Instructions - Since the manufacturer and model is not provided this section does not apply.

In this hypothetical, the effective length exceeds the 35 feet allowed by the Code. So what do you do when, due to the location of the dryer, you have no choice but to have a duct longer than the Code-allowed 35 feet in effective length? The code has changed for 2015 and the answer is found in IFGC Section 614.8.5, which states in part that where the effective length of the duct exceeds the Code allowance of 35 feet, a permanently affixed label must be posted within 6 feet of the dryer connection point. The other option would be to select a manufacturer whose dryer can work with the duct run.

Attempts to Address the Issue

Given the discrepancy between the Code and the manufacturers, some builders are adding a manufacturer and model number to the label; however, manufacturers are always changing models and along with new models come different requirements for the ducting. An owner/occupant may not be able to replace the dryer with the same model, rendering the label ineffective.

In the 2012 IFGC Section 614.6.6, the Code stipulates that concealed ducts must be labeled with the effective length. The label must be permanently affixed within 6 feet of the duct connection.

Problem solved, right? Not exactly. The occupant generally has no knowledge of where the duct runs or how many bends are installed. And given the ever-changing Code and

manufacturer allowances, this information may be pertinent at a later time. Because of this, we believe that both the 2012 and 2015 IFGC are insufficient in there implications for labeling.

We believe that the best practice for labeling the dryer duct would include all of the information an occupant would need to determine if a new dryer is compatible with the existing duct. To do this the label should include:

- The diameter of the duct.

- The total combined length of straight duct.

- The number of 45-degree bends.

- The number of 90-degree bends.

Recommendations/Best Practices

Since labels can be removed and there is no guaranty that the homeowner will clean the duct of lint buildup, Quality Built recommends that the best practice is to keep dryer exhaust duct runs as short and straight as possible.

Additionally, while the code prohibits screens on dryer exhausts, there are exhaust

terminations manufactured with screens and sometimes homeowners or occupants modify the exhaust termination to be screened as can be seen in the photo below.

For those of us with dryers at our residences some of the warning signs of a pending problem include; but are not limited to:

- Clothes take longer to dry than they used to. Most loads should dry in one 35 to 45 minute cycle.

- Clothing is not just warm but is hot to the touch following a drying cycle.

- A noticeable change in the effect of running the dryer on the room temperature.

- If the room gets hotter than it used to when the dryer is running.

- The amount of lint around the lint trap has increased. An indication of lint bypassing the lint trap.

- There is no or very little lint on the lint screen.

- The clothes have a musty odor after drying.

- The dryer vent back draft damper does not open during operation of the dryer.

- A burning odor.

We should be having our dyer duct system inspected and cleaned regularly. This cleaning may include cleaning inside the dryer case itself since lint can leak around some of the seals and accumulate inside the case.

Quality Built, LLC would recommend that builders consider including information on the dryer cleaning in their warranty information. Additionally it would be advisable to include the possible signs of a pending problem with the dryer exhaust and recommendations for regular dryer duct cleaning in their Homeowner’s Manuals.

Conclusion

Proper dryer exhaust duct sizing will not provide a guaranty that a fire will not occur, but will greatly reduce the risk, as the duct is less likely to become clogged. Just because the Code and manufacturers may allow long duct lengths does not mean that long duct lengths should be used. As the builder or installer your risk is increased when you try to defy physics or rely on the users of your product to properly maintain that product.

ABOUT THE AUTHOR

Jeff Hoch is a Forensic Architect, Field

Jeff Hoch is a Forensic Architect, Field

Consultant and Technical Services Technician at Quality Built.

Jeff has been a Licensed Architect for over 18 years.

Jeff has worked as a forensic plans examiner and inspector for 18 of the past 25 years, as well as performing construction quality assurance inspections for over 10 years. He has performed thousands of inspections, while providing plans review, forensic

inspections, and testing in many states. Jeff has an in-depth knowledge of Building Codes, Design Standards, Local Ordinances, Forensic Building

Failure Analysis, and Construction Defects.

You can reach Jeff at: [email protected]